Dismantling of several electro-pneumatic organs

|

In the course of time, the idea arose to acquire an organ for myself. I have described the backgrounds on the page about 'an organ for myself '. In the end, this resulted in several disassembly projects, which are described and illustrated in more detail on my personal website. On this page I give an overview, plus a selection of my own photos. For various reasons I came across organs that had to be disassembled. In general, this was due to closure or major re-use of churches. Sometimes I disassembled these organs for my own use, sometimes I did so because I saw applications elsewhere for the organs or large parts or their pipework. The art that followed was of course to disassemble such an organ meticulously to the last screw and to document this thoroughly. That is not a job to look forward to, but because I am rather handy and analytical and, apart from technical skills, apparently also have physical skills, and because I have a few helpful friends, this turns out to be a viable job. It was not in particular the technical complexity that made this a difficult and stressful job, but especially the logistics and imposed time pressure. Needless to say, it is extremely instructive to completely disassemble an electro-pneumatic or pneumatic organ. (Assembling is of course an even more challenging job, but more about that later.) On this page I show some of my photos of these disassembly projects. Because in fact they were not paid assignments for Rens Swart Organbuilding, I have included the extensive reports with many photos om my personal website. Website Rens Swart OrganbuildingAn organ for myself Personal website Rens SwartThe first find: a small organ with electropneumatic slider chests from Pels What's next? And a swell engine and shutters, blower and windchests Abundantly illustrated: the dismantling of an electropneumatic organ from Verschueren A main reservoir from 1891 June 2016 & February 2018 |

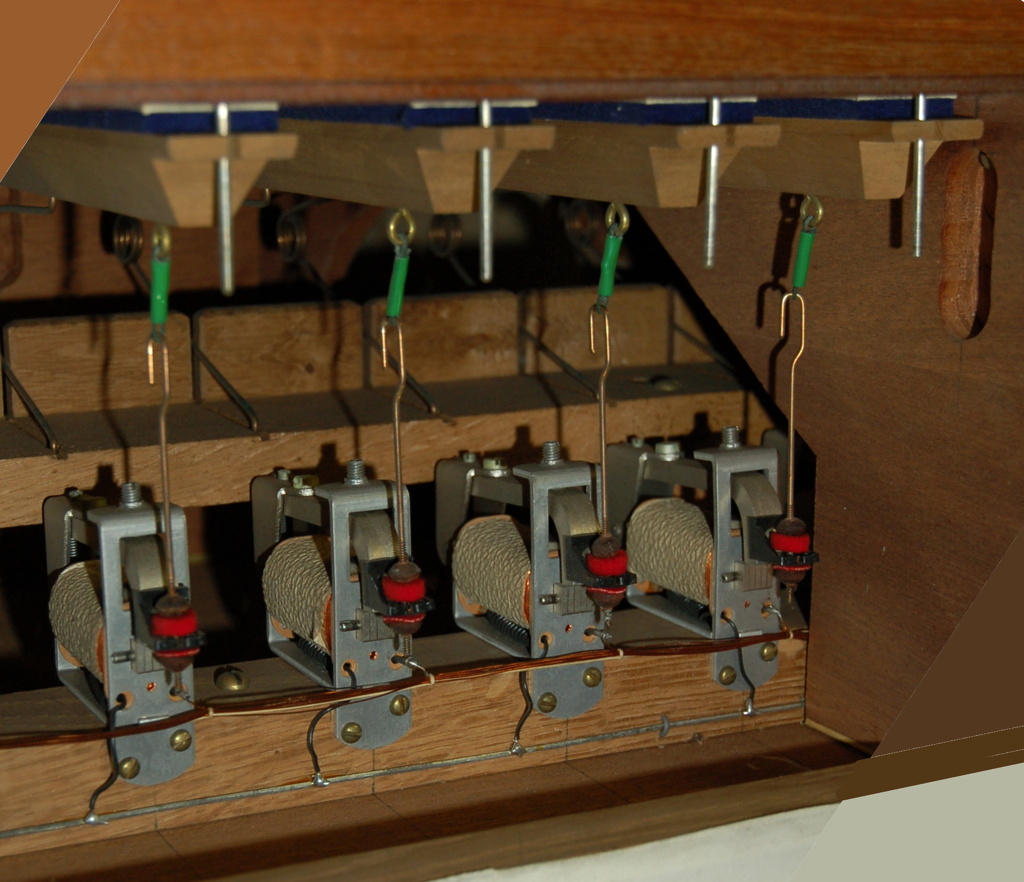

The well built electro-pneumatic slider chests (yes, sure!) that Pels made in 1938 for the Alverna Convent in Aerdenhout, came available a couple of years ago from the church in Geldermalsen to which it had been moved. This organ is the little sister of the organ in Saint-Boniface in Alphen on Rhine, that had been renewed by Pels, and this makes it even more suitable as a choir organ. But the unrealisticly high price asked by organ builders for placing it in Alphen as a choir organ, it came available … a good starting point for me.

The organ was later equipped with direct electric action by Pels en Van Leeuwen. This replaced the electro-pneumatic action in which a deflating wedge bellow pulls the pallet open. From the pallet on, it is just a straight-on simpel slider chest.

The Nasard 2 2/3' is, neatly packed in newpapers, waiting for its next life. Maybe in my warehouse.

Many parts that I was looking for, plus a lot that I did not need immediately, were taken from the organ in the chapel of the Saint-Anne Hospital in Oss, later called Bernhoven. Only the chapel will be retained and incorporated in the new health centre. My dear brother helps with dismantling the swell box and shutters. We had to wear hard hats because it was a building site.

By moving the case panels (? yes!), we succeeded in getting the blower out. ½ horsepower, 70 kg, me and the swell engine in front.

A year later, the 'decor' of the organ had yet to be removed. We then disassembled the beautiful but weathered solid oak side panels and the cone valve chests. We used a scissor lift that was present for the painters, but even then it was quite a challenge … Here you see one of the heavy 140 kg guys in my warehouse. Beautiful shiny mahogany and beautifully made by Vermeulen from Weert.

A friendly organbuilder told me of an organ built by Verschueren in the fifties, moved by him within the church and equipped with electronic action. I could acquire this organ on favourable terms, but only if I would remove it from the church (that was to be sold) to the last screw.

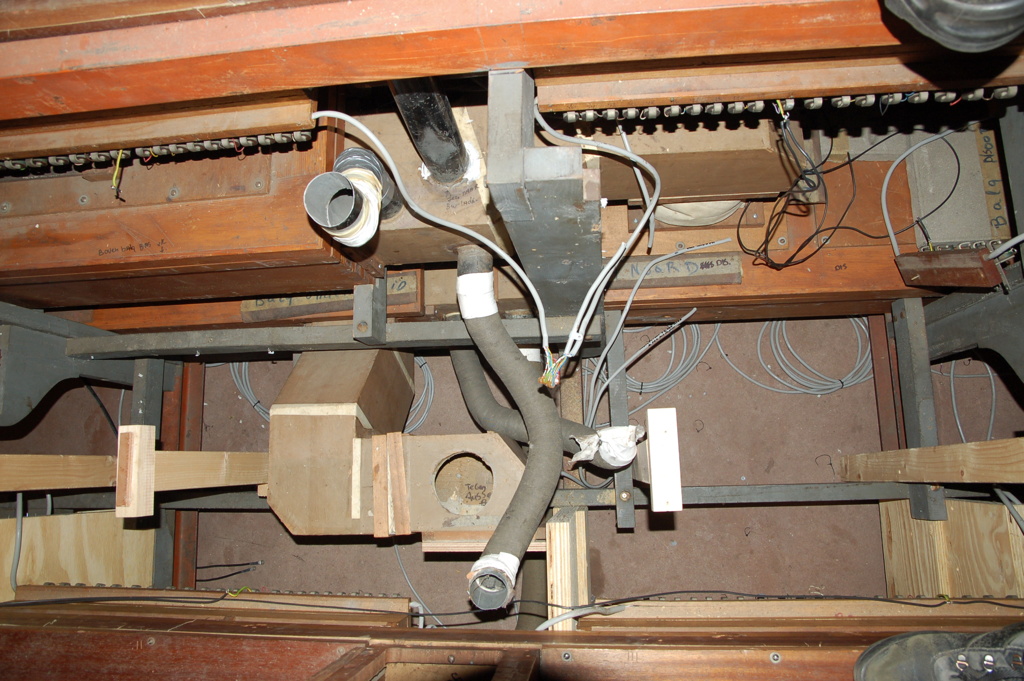

A few hours after the start of the disassembly. We see at the front left the direct windchest of the front prospect of which the pipes already have been removed. Then to the left some larger pipes on a separate small windchest. These chests receive their wind via the black zinc tubes. The wooden box in the middle contains the stop action of the Positif department (second manual). At the rear the Hoofdwerk (Great). The pipes of the peculiar rear prospect have already been removed.

The pipework has been disassembled carefully and was packed in chests with blankets and foam. These Hoboe pipes are rather heavy because of their double led blocks. The sloppy labels date from a previous move, by the way, I wouldn't do it that way.

After the pipework has been removed, the wind channels, wind supply and action cables are disassembled. We have to be sure to understand this before disassembly and to document it via many photos. Then the cabling is cut on a well choosen location to be able to resolder it without too much difficulties. That's the way I am going to do it. All the tens of leads will have to be identified then.

The windchests are the big challenge during the dismantling of any organ. In this case (as is often the case with stop channel chests) the windchest of one manual comes in only one part. Even both diatonic sides (C and C#) are on the same windchest! These weigh, in this case, approximately 130 (Hoofdwerk) and 140 (Positive) kilograms respectively! Also other large heavy parts are waiting for vertical transport. The rest, including the larger pipes and casing parts, were hoisted down by me by hand!

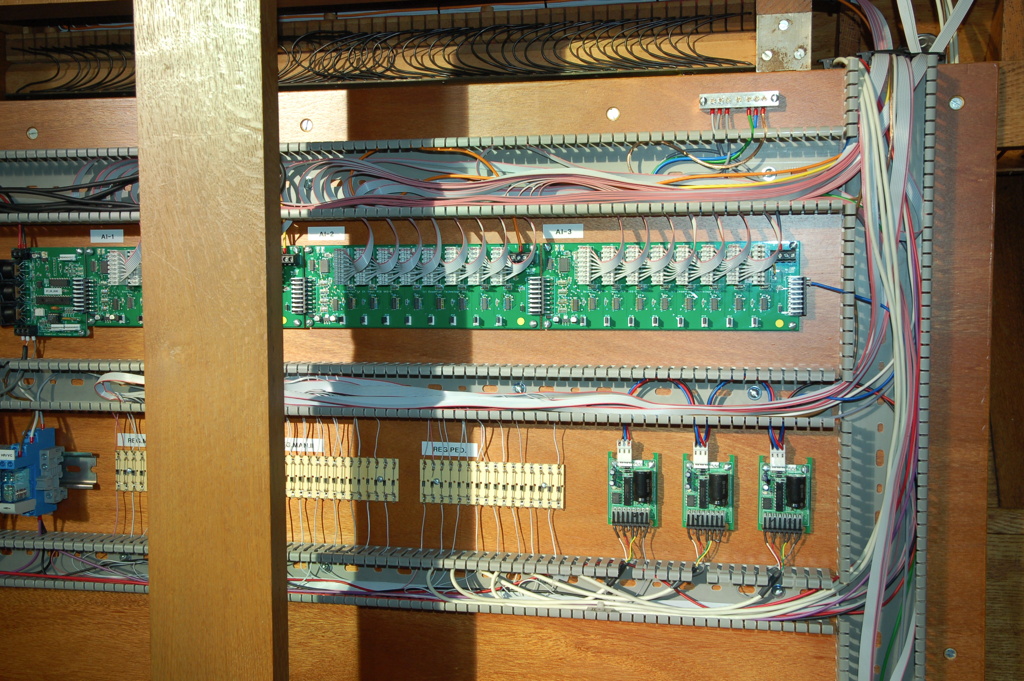

This organ has been converted completely from classical electric action to fully electronic action, on the occassion of the moval from church floor to west gallery. All functions, keys and switches in the console are connected to analog-digital converters on the circuit board and there they are scanned by software loaded in the on-board processor. The complete installation is done very neatly (not by me!). It took me some time to fully understand its workings.

These are the processors at the side of the organ. Mind the huge cable bundles at the bottom, running all over the place in the organ …

I also dismantled the 400 Volt part of the system. Here you see the main switch cabinets with the magnet switches and 24 Volt steering power.

The signal cables ran from the organ upwards to in the tower, then over the stone vaulting, in PVC tubes to the front of the church, where the console was located. I disassembled all this, climbing over the vaulting. A nice way to come in places not often visited, I like that but it has to be said that this is not free from danger.>

For the final dismantling, my friendly organ builder came to help me and brought a ladder lift with him. We started with the blower, the pipe boxes and the electronics installation cabinet. The most difficult were of course the heavy windchests.

Sometimes things go terribly wrong. I had an agreement to disassemble this perfectly conserved romantic Stevens organ in a church closed for years (see the spiderwebs). But it was unexpectedly smashed to parts in one day by the contractor and transported to the waste dump. |

Kind regards,

Rens Swart