Restoration of the sagging prospect pipes of Sint-Rombouts Cathedral in Mechelen

|

Overview:

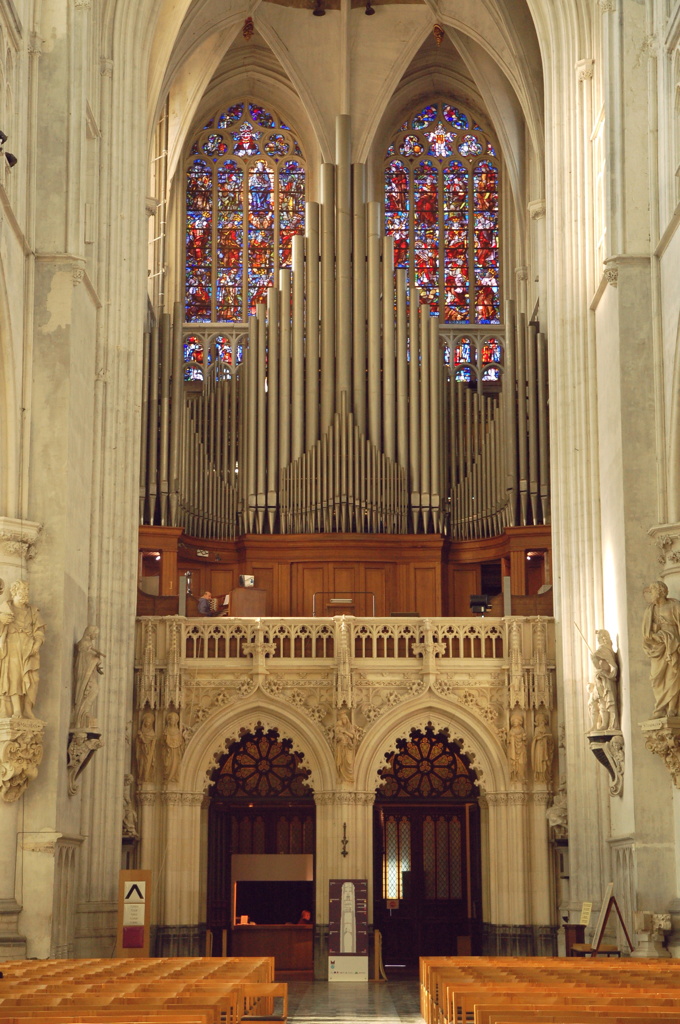

SummaryRens Swart Orgelbouw has been commissioned by the Province of Antwerp to restore the sagging front pipes of the organ of the Sint-Rombouts Cathedral in Mechelen (Belgium) (Rumoldus in Latin or Rumbold in English). The organ was built by Jos Stevens from Duffel in 1923 and modernized in 1958. It is the third largest organ in Belgium and contains almost 6,000 pipes. In 1958 it got a new prospect, with an open 32' made of zinc and two Principals 16' made of organ metal (an alloy of tin and lead). For this assignment, Rens Swart works closely together with Jacques Stinkens organ pipe makers and René Nijsse organ builders. I know the organ very well, as I have worked on it with Orgelbouw Jos Stevens (Jos Stevens did participate in the tender for this assignment). The 16' tin-lead organ pipes in Mechelen have been struggling with sagging feet and mouths for years. In fact, the pipes hang on their hooks, which are actually not dimensioned for that job. The Province has demanded only to deal with these "urgent restoration works". The prospect pipes that are not yet deformed will have to wait until the overall restoration of the organ. This will probably have to wait for at least another decade (or two …), because the entire interior of the cathedral will be restored first. The collapsed feet will be rectified in the workshop in Zeist and supplied with copper inserts, that will be soldered and glued in the feet. This copper insert will carry the entire weight of the pipe (up to 60 kg). In a similar way copper inserts are placed in the pipes around the mouths. Many other pipes will only be supplied with new toes. Four of the zinc front pipes are also being restored. The restoration will be completed at Easter 2019. History of the organFor this overview of the history of the organ of Sint-Rombouts, I used the short article of cathedral organist Peter Pieters in the Belgian organ magazine Orgelkunst 2008–2 as a basis, but most information originates from my own observations. (You are free to use it, but include a reference to me please.) The organ in the Cathedral of Sint-Rombouts of Mechelen mainly dates from 1923. Jos Stevens (1874–1936) from Duffel used some material from the old organ from Henri Vermeersch from around 1850 and from Egidius Van Peteghem from around 1782. It was mainly pipework and hardly or not at all the wind chests. The original Van Peteghem case, at the time in the southern transept, had already been transferred to the new Gothic revival western gallery around 1850 and was retained by Stevens in 1923, but extended to the full width of the nave (or actually that of the huge tower). In 1958, at the instigation of the influential cathedral organist Flor Peeters (1903–1986), the organ was enlarged, extended and modernised by Stevens. Part of the romantic pipework was removed then. In particular strings and low aliquotes disappeared and stops such as Spitsfluit, Gemshoorn and Ranket and mixtures composed of high pitch ranks were added. Furthermore, in 1958 a fourth manual was added, the Crown work. The case was replaced by a screen front with a beautiful curved massive oak case designed by architect Louis Stynen, containing the new Open metal Principal Bass 32'. The wind chests and pipework from 1923 are still the heart of the organ. I think (but this still has to be investigated more thoroughly) almost all manual Bourdons, some Principals and the pedal Bombarde 16' date from Van Peteghem. The Great Cornet and a Fifteenth possibly date from before 1700 and the Subbas 16', Contrebas 16' and Bombarde 32' date from Vermeersch. The Subbas 32' and most reed and flue stops date from 1923. In my view, this is the reason that this 'synthesis organ' sounds so convincing compared to other 'all-round organs'. The wind chests are cone chests, originally pneumatic, since 1958 electro-pneumatic. The wind chests from 1958 are bellow chests (see a project previously carried out on this type of chests). All prospect chests are from 1958; they are electro-pneumatic direct chests. From 1923 a number of direct chests was taken over: probably all pedal chests date from that time. This includes the Principal Bass 16' with 8' extension (actually a Contrebasse), the Subbas 16' with 8' extension, the Pedal Bombarde 16' with 8' extension and the lower octave of the Bombarde 32'. Two new ventils were installed in the pedal chests in 1958 for the extension of the keyboard compass to g1 (with accompanying new pipes, or as for the Bombarde 8' reused old pipes, as far as I can see). Only the 'Small Pedal' division placed at the top of the organ was completely made new in 1958, including the bellow chests. The action, the console and the rather unique electro-mechanical combination action (with a unique 1200 bit memory!) were newly manufactured in 1958. After the construction in 1958, no changes were made to the organ. Only a horizontal trumpet ('en chamade') with only descant pipes was added to the Great in the eighties and a rather loud Trumpet 8' was placed on the roof of the Swell which partly consists of pipework taken from the choir organ. Please read on below ↓ |

The Stevens organ in the Cathedral of Saint-Rombouts in Mechelen. The 32' prospect was built in 1958 together with the extension and modernisation of the organ, that mainly contains parts of the 1923 Stevens organ.

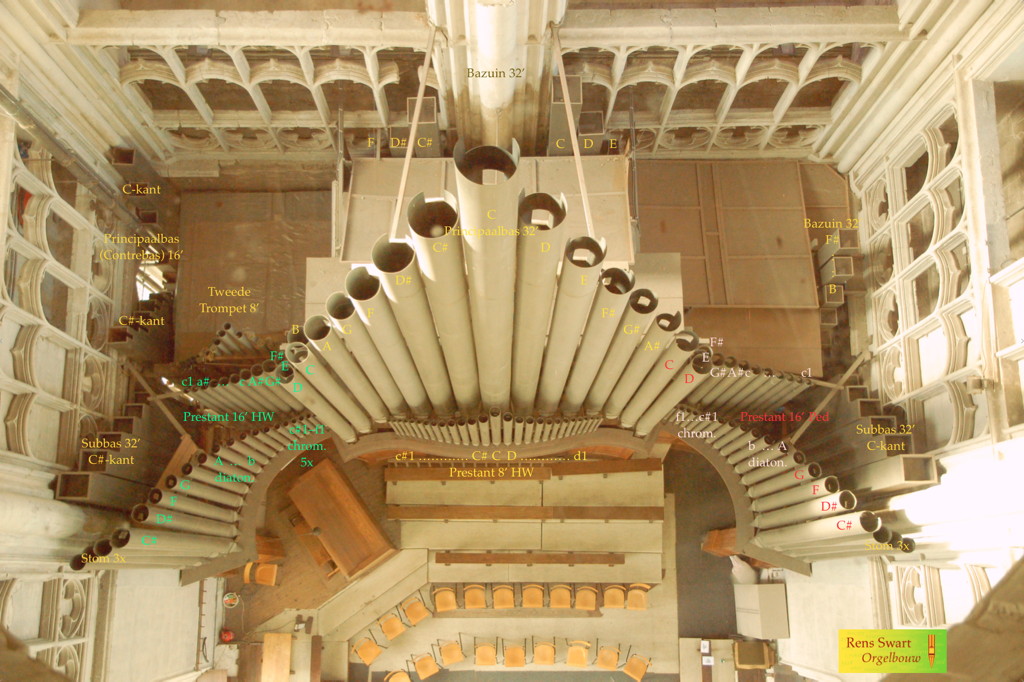

The organ as seen from above, wow! I have indicated which visible pipe is which and to what stop it belongs.

Yes, Stinkens has photos from 1958 in their archive! It is interesting to see how the workers of Stevens and Stinkens in 1958 hoisted the pipes into place, using a hoist from the vaulting, without any scaffolding, ladders or protection of the balustrade. We definitely do that different this time! Photo Jacques Stinkens Orgelpijpenmakerij, Zeist |

Current status of the prospect pipes | |

|

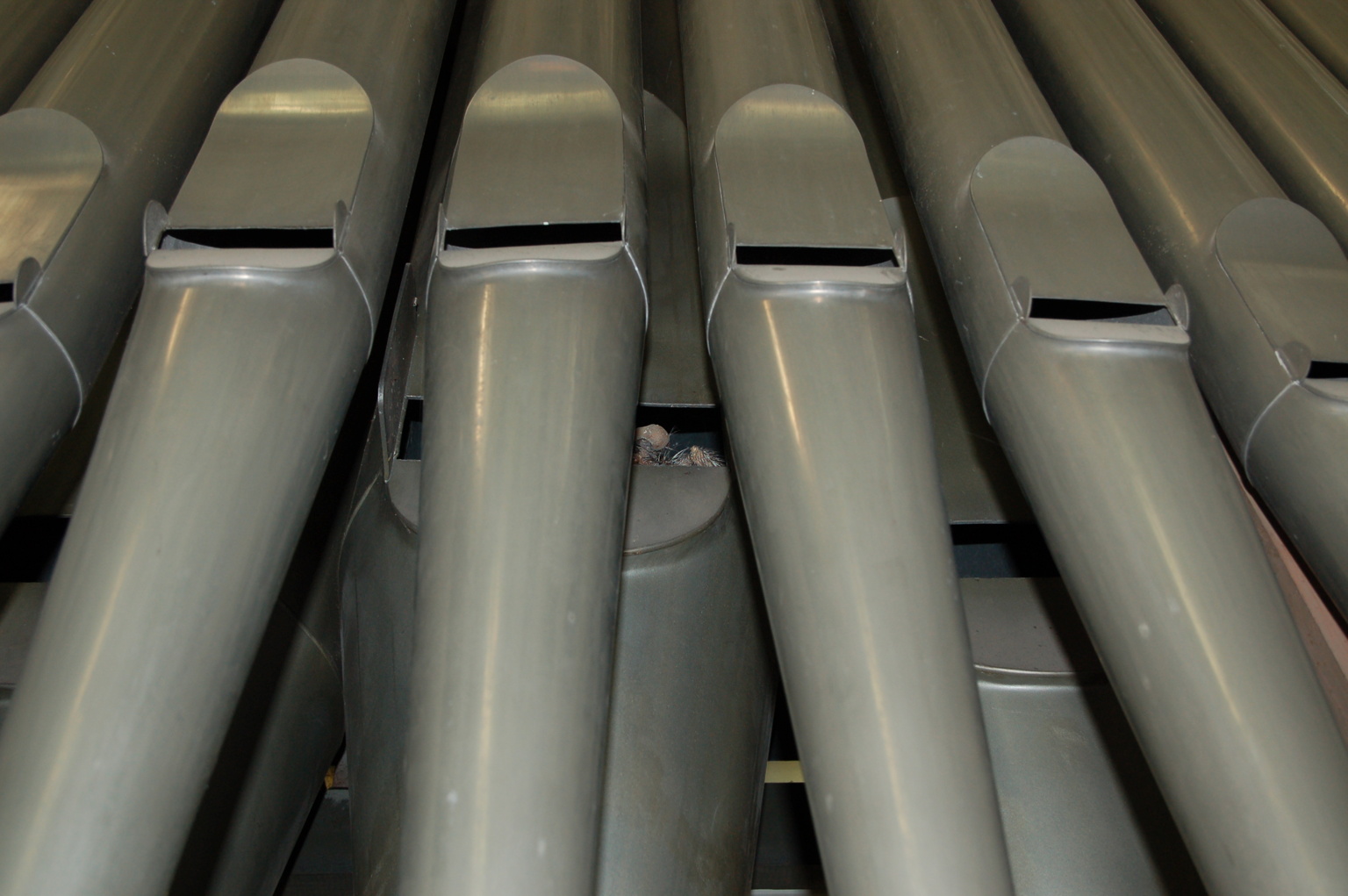

The prospect pipes (also called front, display or façade (with cedille!) pipes) were made new in 1958 by Stinkens in Zeist. All prospect pipes are speaking, except for the three 16' pipes at either side near the tower walls. All pipes are of high tin content, but the 18 largest pipes in the central screen are of zinc (yes, that's an even number, think about that!). The zinc pipes consist of the lower octave of the Principal Bass 32' and the C, D and E of the Prestant 16' from the Great and Pedal departments. The rest of the lowest two and a half octave of the Prestant 16' of the Great is in the two left screens and that of the Prestant 16' of the Pedal is in the two right screens. The 27 pipes in the middle front screen are from the Prestant 8' of the Great. All pipes larger than say 12' show collapsing feet and bodies around the mouth. All smaller pipes show collapsing feet toes. The pipes of the rear screens to the left and right have a huge extension length, which makes the feet also vulnerable to collapsing. Their bodies have been strengthened in the past by soldering a steel profile on the back. Organ consultant Jef Braekmans decided, because the Province of Antwerp demands to do only the really urgent jobs now, to only restore the 6 or 7 largest tin pipes at either side. On our suggestion, we do that by adding copper inserts and retaining the original feet because copper does the job better than thick tin and in this way there will be no colour difference due to aging tin. Many other pipes only get new foot toes. Most zinc 32' pipes show collapsing zinc foot toes, but they are left in place. It would be quite a job to get these 200 to 300 kg 11 meter monsters out, but we would have preferred to restore them too. Remarkably, four of the smallest 16' zinc pipes show slightly deforming feet. The larger pipes don't, in my view because their bodies have less freedom of movement because they are hung on hooks on two different heights. The four deforming zinc feet are also supplied with supporting foot inserts. December 2018 Please read on belooooooow ↓ |

The sagging of the feet of the pipes and the collapsing of the bodies near the mouths is very clear. Pipes hang mainly on their hooks, which is quite dangerous.

Also the toes of the feet collapse as the about 80 kg above them is too heavy.

The foot has deformed directly below the languid. The body more or less sagged over the foot and the foot has lost its strength.

The body has sagged to the foot, so the metal at either side of the mouth has collapsed. As a result, this pipe will speak badly or not at all.

This is an example of a 16' pipe with a copper insert around the mouth. (Languid and cut-up are not perfectly straight.)

An unusual view on the right hand side of the organ. It is very clear that one prospect pipe is collapsing, as it bends towards the rear.

The Pedal Prestant 16' at the right side of the prospect faces the same problems as the 16' pipes on the left hand side. Most feet will get new copper inserts after rectifying.

The smallest pipes of the huge 32' zinc pipes are actually the largest of the Pedal Prestant 16'. To the right the tin pipes of the Prestant 16' and to the left the tin pipes of the Prestant 8' of the Great.

Some of the zinc pipes also show deformation of the feet and body. This will be rectified.

The toes of the 32' pipes collapse due to the weight of about 200 or 300 kg. This will not be restored during our restoration job, as it is not immediately dangerous. This will have to wait a couple of years. Or decades.

The collapsing is clear. This is dangerous, as the pipe stays only upright because of its hook, that is not dimensioned for that job.

The toes of the feet of the rear screen pipes show collapsing as well.

An unusual view on the organ. |

Disassemly of the prospect pipes | |

|

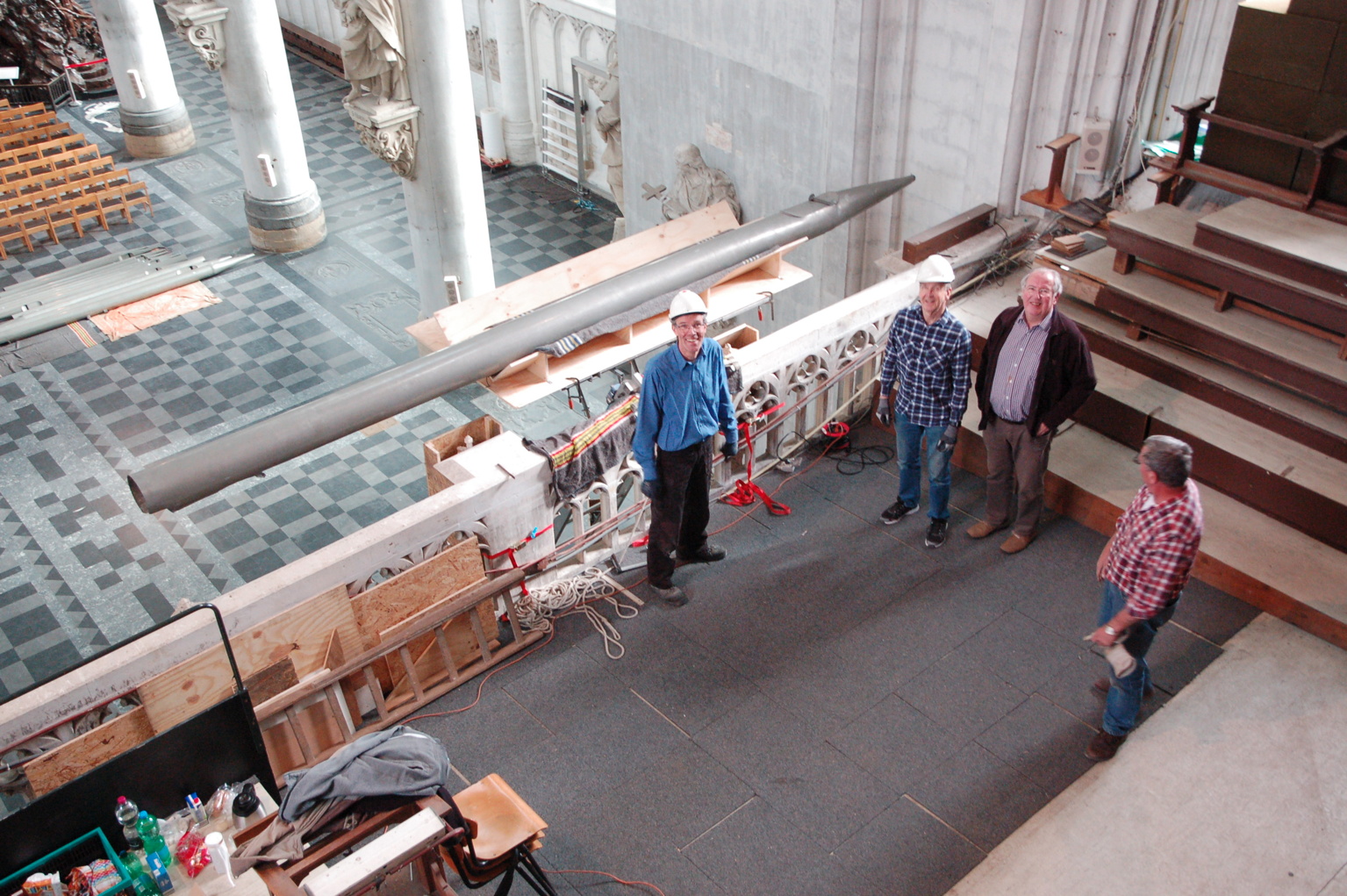

11 and 12 March 2019 we have lifted or hoisted the 51 pipes out of the organ prospect. As we will use a mover's lift for transport of the pipes from the gallery to the church floor, we have to take care for the vulnerable sandstone pinnacles of the gothic revival balustrade. As we have to lift the 60 kilogram pipes by hand to the lift platform, this was for me probably the most challenging part of the job. We made wooden protection boards that fitted as tight as possible to the irregular shape of the pinnacles, to leave as much room for us as possible. The prospect pipes have been marked and numbered according to the consultant's scheme. While climbing in the back of the prospect, it became clear how previous organ builders had tried to prevent the pipes from collapsing. Some pipes had steel or brass profiles soldered to them and from many the pipe feet had been renewed with limited success. After clearing the gallery by getting all steps and chairs and podium elements out of the way, we started to erect a movable scaffolding to come as close to the prospect pipes as possible. On top of the eight meter high scaffolding, I attached an electric hoist. In particular during lifting the heavy hoist on a rope to the top of the moving scaffolding, and attaching it to the scaffolding, fear of heights is not recommended. The smaller pipes are lifted from the organ prospect by hand, for the larger pipes we use a small hoist. A pipe harness ('pipe trousers' in Dutch) is used to be able to lift the pipes, that weigh up to 60 kilograms. This leather harness, lined with soft material, is clipped around the feet and while lifting it will secure itself. A pipe is slowly lifted until it is free from its hook. In this case there were also long steel hooks pointing downwards. It was difficult to free the upper hook and then tilt the pipe to free it from the upside-down-hook. The pipe then was moved to the gallery floor, laid horizontally and carried over the balustrade onto the lift. It is a pleasure to work with a team consisting of handy, careful and strong men! André Swart (my brother), Ad, René, Sjaak and Kees. Oh yes, and myself. The prospect will be left as it is now. Including the dead bird trapped in the largest 32' pipe that became visible after removing the 8' pipes in front of it. I leave the scaffolding also in place. In four weeks, we are back! The photos to the left give an impression. For an album of some 40 photos: scroll down! ↓ |

We protected the sandstone pinnacles of the gallery balustrade with a custom made tight wooden box to be able to manoeuvre freely with the six meter long pipes.

A pipe harness is used to be able to lift the pipes, that weigh up to 60 kilograms. This leather harness, lined with soft material, is clipped around the feet and while lifting it will secure itself. Behind André you see the six largest Subbas 32' pipes from the do-side.

A pipe is slowly lifted until it is free from its hook, in this case two hooks, one of them poiting downwards … The pipe then was moved to the gallery floor, laid horizontally and carried over the balustrade onto the lift.

A pipe on the lift, ready to go to the cathedral floor. From left to right: Rens, Ad, organ consultant Jef and René.

After the pipes have been removed, the racks are dusted and vacuum cleaned, primarily to inspect the racks on strength. What a beautiful curved massive oak organ case! We are looking straight up here, to the cathedral nave vaulting. Fear of heights not recommened, although it is only 8 meter.

The Stevens organ in the Cathedral of Saint-Rombouts in Mechelen with the 16' pipes removed. The 32' pipes and many 8' pipes will stay in place because they only show limited deformation and are regarded as safe. |

|

By clicking on any of the photos below, you can click through all of my 36 selected photos. Click on the arrow symbol at the right to view the next photo, click on the photo itself to end the slide show. Mind the photo with the dead bird trapped inside the largest 32' pipe. And some painters tend to portrait themselves in a corner of a painting …  Apenootjes Many of the larger pipes have been supplied with an extra hook, hooking on a steel strip that points downward, contrary to the pins for the upper hooks. This makes disassembly tricky. Dit werkt niet. ⧁ | |

Intermezzo: funeral cardinal Godfried Danneels | |

|

On 14 March 2019, the well-known cardinal Godfried Danneels died. He was archbisshop of the Mechelen diocese for thirty years. On Friday 22 March 2019 his funeral took place in the Saint-Rombouts Cathedral in Mechelen. The cathedral was fully occupied and politicians and king and queen were also present. I went to the cathedral to take care of the dismantled organ, as far as necessary. And I climbed silently on my own scaffolding to have a good view and take photographs. I have always enjoyed doing uncommon things. Including walking over the front base of the prospect during the mass to cure a leaking windway that made a strange noise when the tone was used with the prospect pipe removed. Cathedral organist Peter Pieters stoically did his work while sitting almost buried under the scaffolding. As the organ has about 6,000 pipes, the 51 largest can be more or less missed … |

|

Restoration of the pipes | |

|

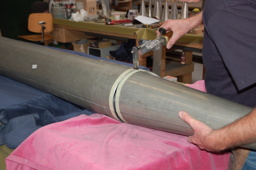

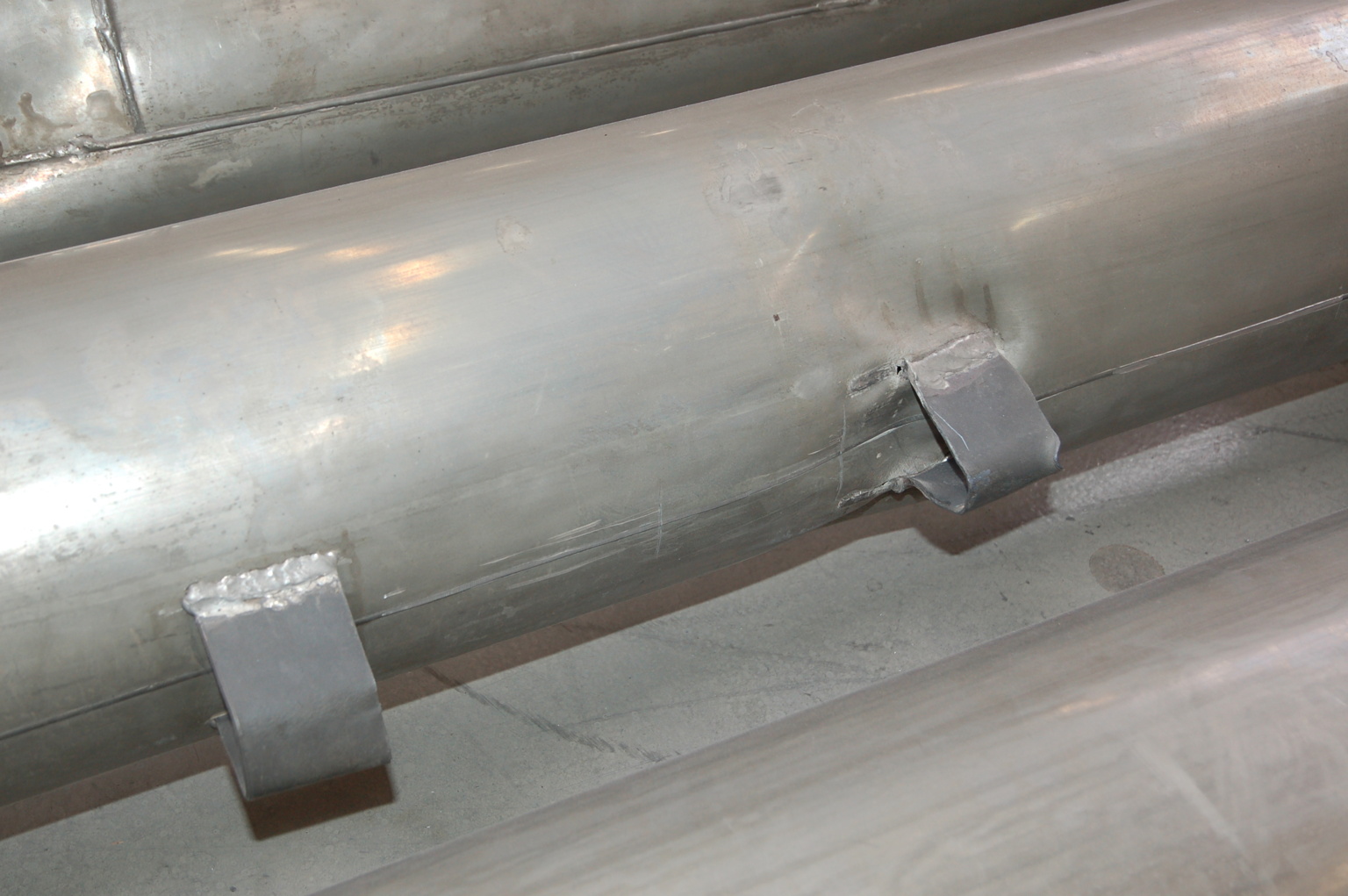

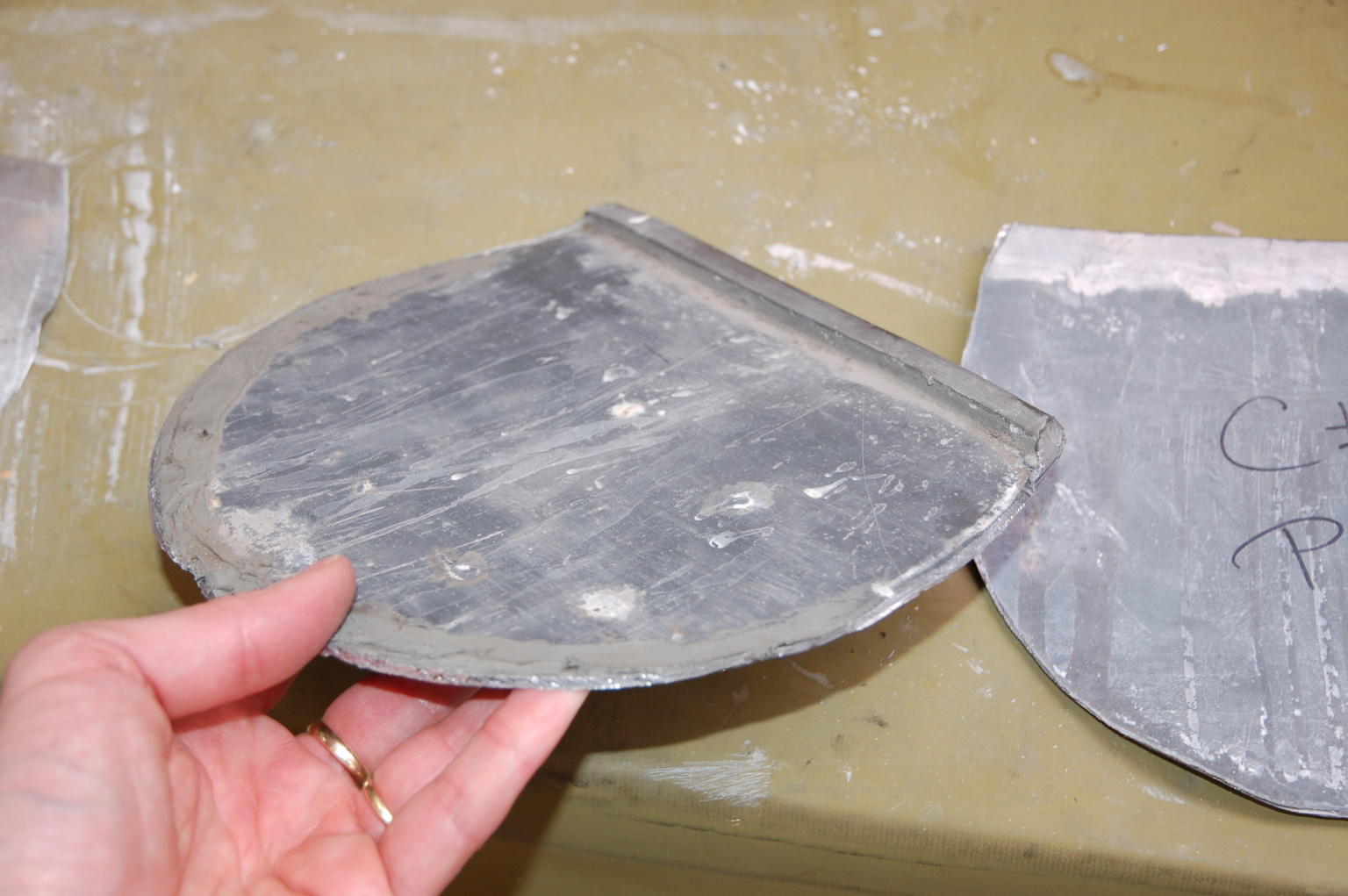

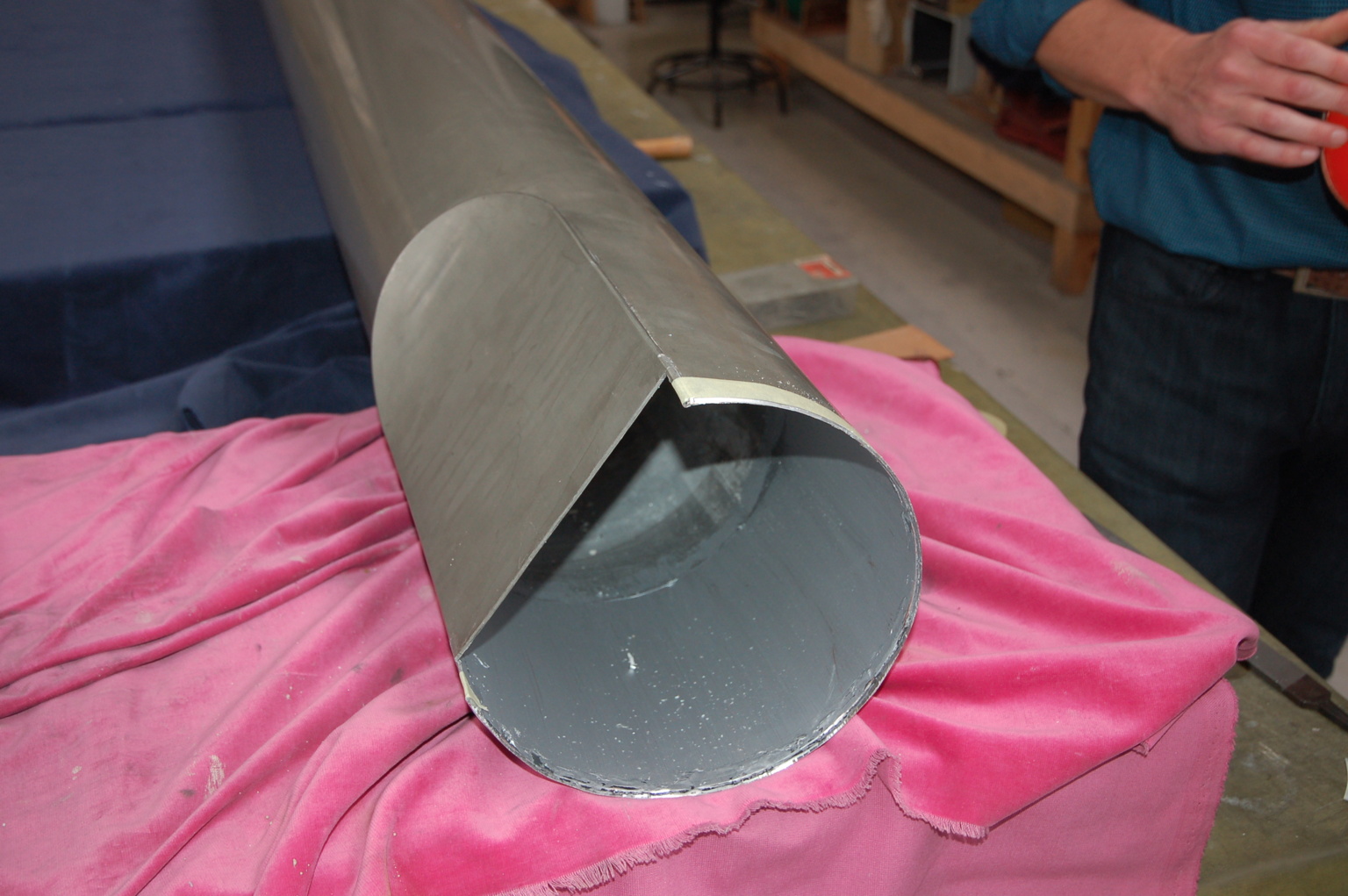

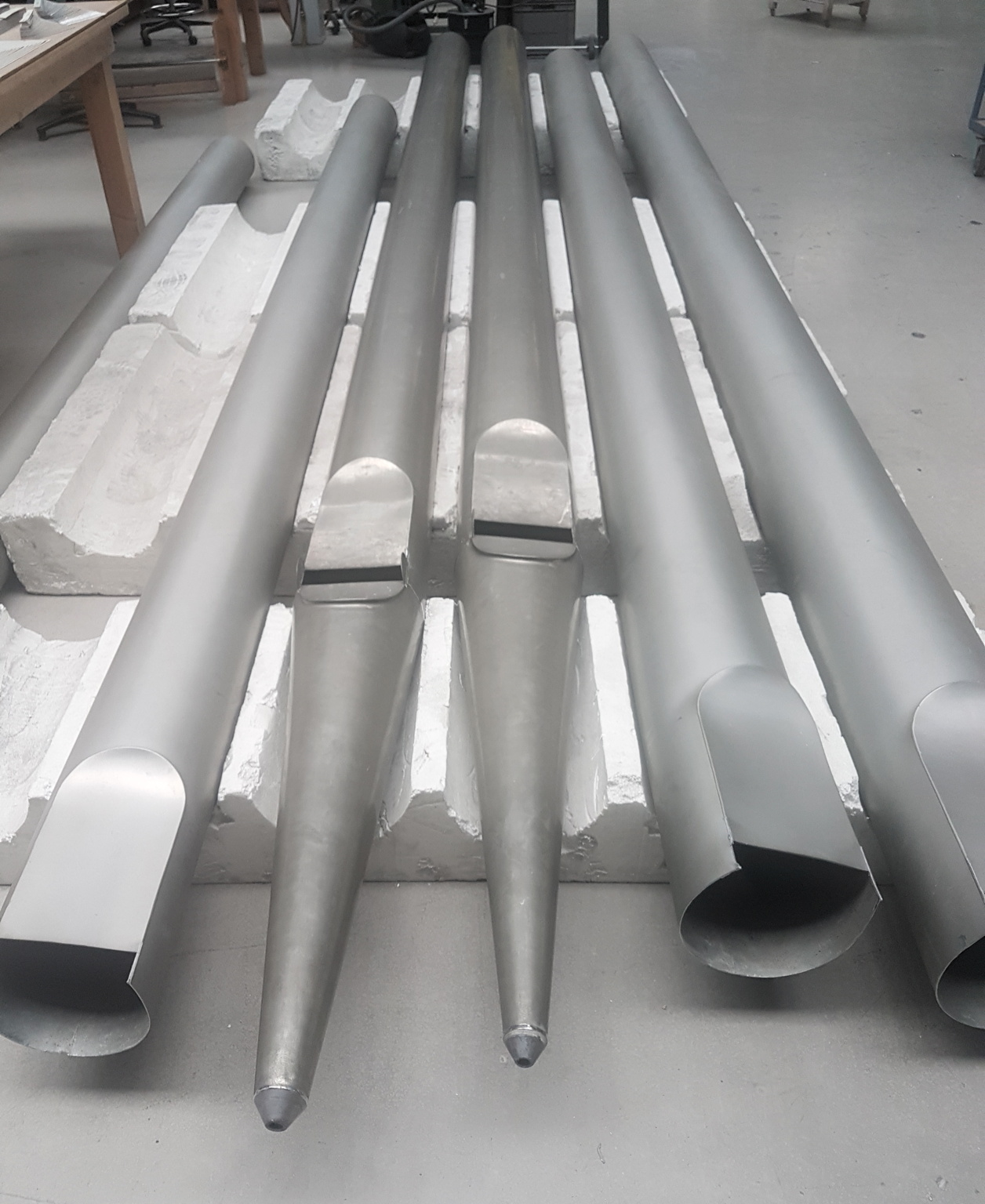

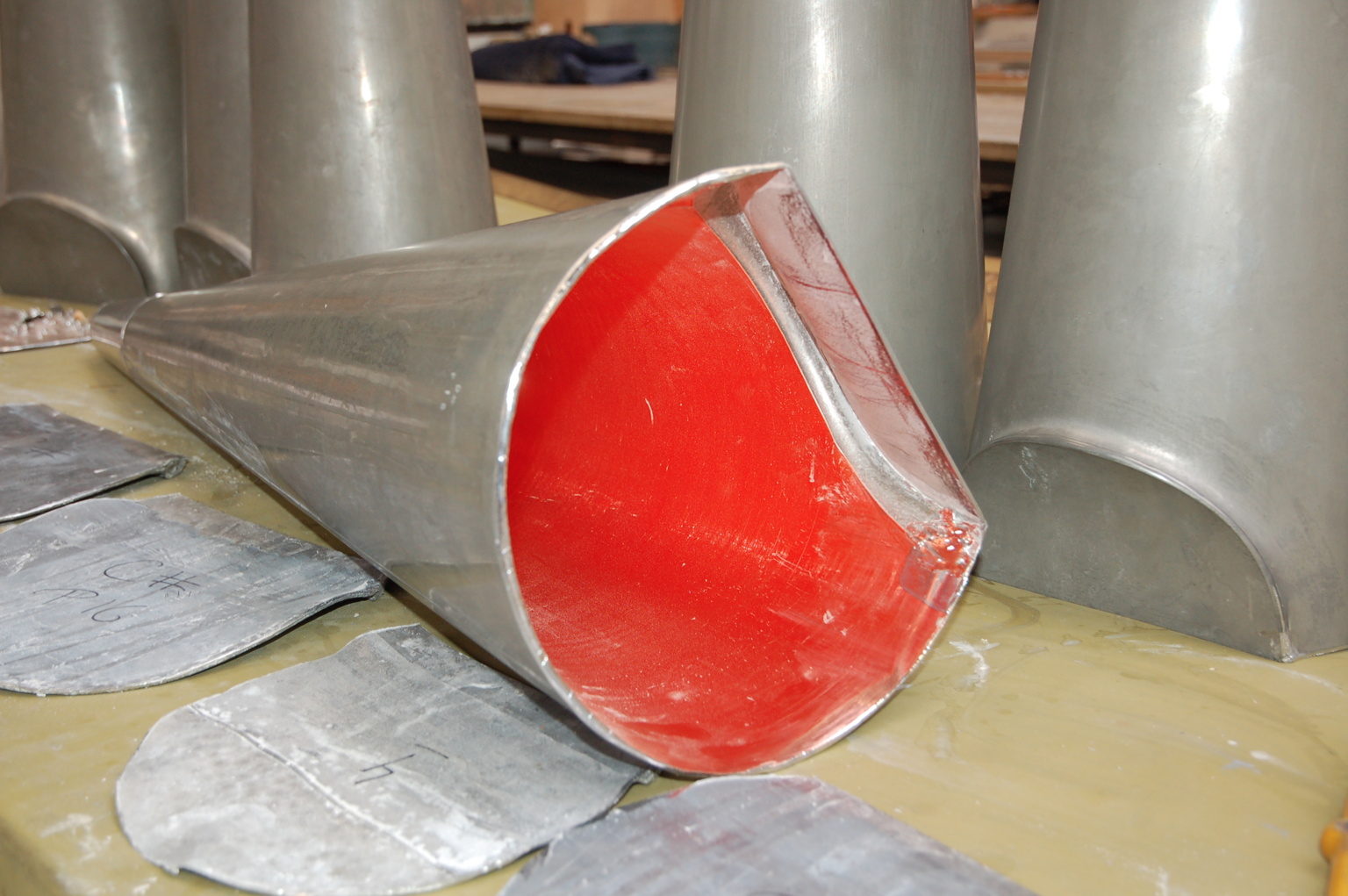

The 51 prospect pipes were transported to the world-famous Dutch specialised organ pipe maker Stinkens in Zeist. As they make pipes for organ builders all over the world, some of which don't want to admit that they hire Stinkens, they are used to massive numbers of large pipes. But to get two complete tin-lead Prestant 16' stops into their workshop was even for them unusual. The smaller pipes only got new molded foot tips. This concerned the smaller pipes of both Prestant 16' stops and seven pipes of the Great Prestant 8' in the front screen. The higher pitched pipes in the straight pipe screen in the second row to the left and the right have very long overlength. These have been reinforced with steel wires in the past. Because of their width-to-weight ratio, they got new copper foot inserts. From all taller pipes, the feet were separated from the body. The feet were rectified and new heavy gauge foot tips were soldered on. From red copper sheet, new feet were formed, fitting exactly into the tin feet. The copper inserts were then cut to fit, glued and soldered to the tip and the upper edge of the feet. The languids were rectified and polished. The larger pipe bodies were rounded by rubbing them with an iron bracket, that was covered with leather because polishing the pipes was not intended. Green soap was used to lubricate the rubbing. This was at the same time the only cleaning done to the pipes. The zinc pipes were not rubbed or cleaned at all, as the rough aluminium spray paint makes this impossible (why don't organ builders use a clearcoat as in the car industry??). Most larger pipes also got a copper insert around the mouth. The copper was painted grey from the inside to blend with the tin, as fas as one could look into the mouth of the pipe. Some pipes had bodies even deformed near the mouths: for these, inserts were provided from the languid to above the mouth. For this the whole mouth was removed. All pipes were assembled by soldering to the measurements that were done before the pipes were taken apart, although this could not be done very exact because of the heavy deformation of the feet. Because of the very high heat capacity of the heavy metal pipes, a heavy gas heated soldering iron was used for the soldering and the pipe bodies were pre-heated with a heat gun. Many pipes had deformed hooks, not surprisingly as they for a good deal hang on them. Some pipes had been secured by using iron wire around hook and racks and the wire had been dangerously pulled into the hook metal. Many new hooks were supplied. The photos to the left give an impression. For an album of some 30 photos: scroll down! ↓ |

Part of the patients in the waiting room, patiently awaiting their treatment. Even for Stinkens, it was extraordinary to have two full metal Prestant 16' stops in their workshop. From one organ!

Note the two hands, corroded into the metal in the past. This is due to acids into the person's skin and cannot and will not be cured.

Those poor feet … hopeless. But there is hope!

These 16' feet have been disassembled from the pipe bodies. The languids were also taken from the feet, otherwise we cannot insert the copper feet. All dimensions have been accurately measured to help assembly and prevent extensive voicing work.

These 16' feet have been supplied with new heavy gauge molded toes and one with a partially new foot. Two other feet have already been replaced partially in the past.

A copper sheet is placed into the foot. This is before fitting and soldering (this is not one of our pipes).

The copper insert has been made to fit and glued and soldered into the 16' foot. The languid still has to be soldered into place.

A couple of copper inserts waiting to be assembled to the pipe feet. Yes, this was a huge job.

After the foot has been removed, the body of the tin-lean 16' pipe is shifted over a last. Using a brace covered with leather and green soap, the pipe is rubbed, primarily to remove the dents and make it round again. This is the only cleaning applied to the pipe.

Foot and body are assembled again with a heavy soldering iron. This is not easy as the physical heat capacity of the metal is huge.

These pipes are ready (well, the six I mean). Note the weird colour difference on the three pipe bodies to the left. These are the three pipes to the far left in the organ prospect in Mechelen Cathedral. Apparently sheets of metal have been used back in 1958 with a slightly different tin-lead alloy, leading to different oxidation. We leave it this way. |

|

By clicking on any of the photos below, you can click through 29 selected photos. Click on the arrow symbol at the right to view the next photo, click on the photo itself to end the slide show. Installation of the restored prospect pipes | |

|

After restoration of the organ pipes, they had to be replaced in the organ prospect. As my Haynes car workshop manuals say, after a couple of paragraphs with frightening descriptions and photos of a repair job to be done: "Installation is the reverse of removal." If it were that simple! Actually I did make only a couple of photos, some with my phone as while climbing I left my DSLR on the gallery and only had my phone with me. There is not much news. All the pipe racks have been inspected and they were in good order. However, as we did not want to reuse iron or copper wire to secure the pipes on the racks, some extra measures were necessary. The two pipes on the front corners had hooks on two levels, as the rack to the wall is higher than that to the back. I grinded a steel profile and mounted it on top of the upper rack to be able to hang the pipes on two racks. However, on the right hand side the hook was too low and a wire was used, as an extra over the lower hook. The small wooden racks that protrude from the 32' screen to hang the 'smallest' of the 32' zinc pipes (still 6.5 metre) (see yellow arrow in the photo to the right) were very unstable and even shifting the hooks over the pins was problematic. I welded steel hooks to support and stabilise them. However, how to get there?! It is at about nine meter over the gallery floor and no ladders could get there. I decided to screw a wooden beam to the structure of the prospect. With some athletic movements I could climb onto it, seven meter above the floor and while holding myself I managed to drill and screw the welded hook under the rack. On the left hand side it seems easier as the scaffolding was still in place (a day before arriving of the pipes from the workshop), however there was a gap of more than a meter. As my legs are rather long, I managed to bridge it, one foot on an empty pipe rack, the other one on the scaffolding. I even managed to get back to the scaffolding after mounting the steel support under the rack. So the 32' pipes are safely held by their hooks again. Wait, that's a lot of text for a minor point. Well, it was a challenge. The largest pipes had not only a hook for hooking at a pin on the rack, but also a lower second hook for a steel strip screwed to the back of the pipe rack. This strip points downwards while the pin points upwards of course! This makes it necessary to disassemble the downward strip and only assemble it again after the pipe is brought in place. Problem is that after all pipes have been installed, it is difficult to impossible to get at them … Behind the left front prospect pipes is a little plank at about seven meter height, to get to the upper part of the 16' pipes for tuning and securing. This can be reached by climbing from the swell roof over a small beam near the Subbas 32', However, at the right front prospect pipes there was no plank like that. With Ad, I added two small beams to 'walk' over, but it can only be reached after climbing out of the gothic triforium over a small beam with the Subbas 32' as the only possibility to hold oneself. The four 32' pipes that got to the workshop to get new copper feet inserted, were not sprayed after assembly. As you know, zinc has always to be sprayed to prevent it from becoming completely black. Usually aluminium metal spray is used, but this come in about 3526 different shades of grey, so it will just never match. We have left it as it is. After all pipes had been reinstalled, the voicing and tune were checked. Mind you, all pipes on direct chests, including most pedal stops and all prospect pipes, are on a 120 mm wind pressure, yes, including the Great Prestant 8'. Still not all replaced pipes speak well. Some pipes get too little wind due to leaks in the windway the prospect cabinet. The notorious water damage from September 2018 apparently has even affected some of the prospect chests: the action of at least one pipe is damaged. For some pipes, metal sheets too thin have been used, leading to an instable tone. Those problems will have to wait for the full organ restoration. Furthermore, sometimes problems occur in the electric coupler action and contact cams in the console, as e.g. the Pedal Prestant 16' has an 8' extension. Some of the larger prospect pipes are fed via a membrane pallet which is leaking or malfunctioning, leading to weird effects. Anyway, it is satisfying that I understand what the problems are in this complex machinery. I will fix this later on during normal maintenance work. Maundy Thursday, 18 April 2019 The photos to the left give an impression and I have commented on them. For an album of a 40 photos: scroll down! ↓ |

With the prospect pipes removed, one gets a good view on the upper departments of this gigantic organ. Behind the open Principaalbas 32' with the metal Prestant 8' in front of it, we see the chest for the high stops of the Great organ, added in 1958. Behind it is the Kroonwerk, the fourth manual. Behind that, we see the wooden resonators of the full length Bazuin 32'. At the right we see the Positiv department. Af the far left behind the scaffolding the six largest pipes of the Subbas 32' do#-side.

The small wooden racks (yellow arrow) that protrude from the 32' screen to hang the 'smallest' of the 32' zinc pipes (still 6.5 metre) were very unstable. I welded steel hooks to support and stabilise them. However, how to get there?! You cannot stand on the organ 'roof'. It is about nine meter above the gallery floor …

I screwed a wooden beam to the structure and climbed on it, at seven meters high. This way I could drill and screw the hook onto place, with one free hand (OK, sometimes two …). Note the feet …

The steel support is in place.

The other side could be done from the scaffolding, bridging the one meter gap between a pipe rack and the scaffolding.

The pipes arrive again at Mechelen Cathedral.

The pipes on the marble floor of the Saint Rumoldus Cathedral.

The rectified feet and bodies, new solder joints and pipe toes tell the work done.

The electric hoist had to be … hoisted back (by hand!) in place at the top of the scaffolding. We only use it for the larger pipes (> 12' or so).

Three pipes ready to get back into the prospect. One of them has the double leather harness attached. View from the top of the 8 m high scaffolding.

Pipes back in place.

The prospect is a beautiful design by architect Louis Stynen (that's not modernist architect Leon Stynen!), although the 'neo-baroque' curves can only be appreciated while looking from slightly aside, not from the cathedral floor.

The largest pipes had not only a hook for hooking at a pin on the rack, but also a lower second hook for a steel strip. This points downwards! This makes it necessary to disassemble the downward strip and only assemble it again after the pipe is brought in place. We also see the new steel profile I provided for the upper hook of the cornet pipe, instead of tying it with a wire to the pin that sits too far back on the rack.

To be able to get to the upper part of the 16' pipes, behind the right hand prospect pipe screen we made a similar 'convenient walking plank' :-) as present behind the left hand screen.

Although … one can only get there by climbing out of the gothic triforium over a small beam with the Subbas 32' as the only possibility to hold oneself.

In this way, I could fix the 16' pipes to their racks with felt and tune them as far as necessary. The finishing touch …

The restored 1958 Stynen prospect in all its glory with the incredible 1721 pulpit. We are ready! |

|

By clicking on any of the photos below, you can click through 40 selected photos. Click on the arrow symbol at the right to view the next photo, click on the photo itself to end the slide show. | |

Kind regards,

Rens Swart